1. Low First Cost

Soil-cement is often more economical to construct than bases through the use of soil material on or near the commercial paving site.any in-place non-organic,low plasticity soils can be used.Also,nearby borrow soil can provide an excellent material source,requiring lower cement contents than clay and silt soils.Borrow soils do not have to be expensive base-course material;almost any granular material is suitable.

2. Fast Construction

Modern methods and equipment make soil-cement processing simple and efficient.In-place soils are processed at the paving site.When borrow soil is used,itn is usually mixed in a central plant the borrow source,the hauled to the paving site to be compacted. Finished to grade,and cured.There is no mellowing period or other delays in the construction process.In addition,soil-cement is stable immediately after construction and gains strength rapidly.

3. Recycling of Existing Materials.

Making good soil-cement out of old flexible pavement is nothing new;it has been done for years.Failed flexible pavements contain materials that can be salvaged economically by recycling-breaking them up,pulverizing them,and stabilizing them a minimum quantity of Portland cement to make a new soil-cement base.There is no disposal problem as is commomly found when old pavements are dug out.Since approximately90% of the material used is already in place,handling and hauling costs are cut to a minimum.Many granular and waste materials from quarries and gravel pits can also be used to make soil-cement,thus conserving high-grade materials for other purposes.

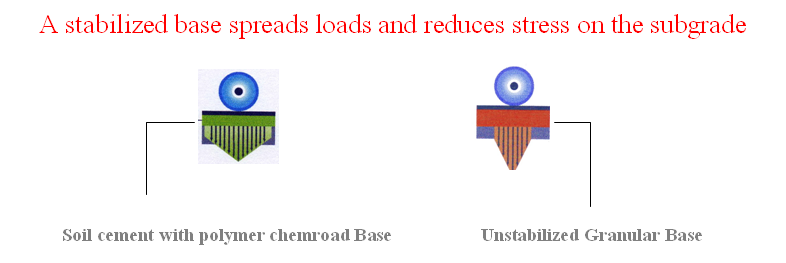

1.Stiffness

Soil-cement is a low-cost pavement base offering the feature most essential for long-lasting parking and storage areas-stiffness.Large paved areas must maintain their original grade and must not develop depressions or potholes if they are to drain freely during rains,thereby preventing puddles and damage from water that seeps through and weakens the underlying soil.The stiffness of a cement-stabilized base acts to distribute loads over a wider area,reducing subgrade stresses and allowing the maintain its original grade for many years without costly resurfacing or repairs.

Stabilized Base vs. Unstabilized Base

Soil-cement does not rut or consolidate.As a cemented material,it does not soften when exposed to water.When rutting occurs in an unstabilized base material or the underlying subgrade soil,a simple overlay of the pavement surface is insufficient to correct the cause of the rutting.With a stabilized base,rutting is confined to the asphalt surface layer and is relatively simple and less expensive to correct.

2. Great Strength

Cores taken from soil-cement pavements furnish proof of its strength. Samples taken after 15 to 20 years show considerably greater strength than sample taken when the pavement was initially built. Because the cement in soil-cement continues to hydrate for many years, soil-cement has “reserve” strength and actually grows strength and actually grows stronger.

Soil-cement thickness requirements are less than those for granular bases carrying the same traffic over the same subgrade. This is because soil-cement distributes loads over broad areas. Its slab-like characteristics and beam strength are unmatched by granular bases. Strong, stiff soil-cement resists cyclic cold, rain and spring-thaw damage.

3. Superior Performance

More than 70 years of collective experience have demonstrated that different kinds of soil-cement mixtures can be tailored to specific pavement applications,all achieving superior performance as a result of soil-cement’s strength.Thousands of miles of soil-cement pavement in every state in the United States and in all the Cannadian provinces are still providing good service at low maintenance costs.

Cement-treated bases are designed to be virtually impermeable,so that even under frost conditions no ice lenses can form in the base layer.With a granular,unbound material,if poor drainage exists or groundwater rises,the base can easily become saturated,causing significant strength losses.The cement-stabilized layer,on the other hand,will maintain significant strength even in the unlikely event it becomes saturated.

The higher stiffness of cement-treated bases leads to lower pavement deflections and lower asphalt strains,resulting in longer fatigue life for the asphalt surface.The use of soil-cement actually reduces the occurrence of fatigue cracking,a common pavement failure.